- Home

- Products

- OEM&ODM Services

- About

- Applications

- Resources

- Blogs

- Contact

Views: 0 Author: Site Editor Publish Time: 2026-02-10 Origin: Site

Why do some aluminum sheets last longer and look better over time? An anodized aluminum sheet stands out for durability, corrosion resistance, and surface quality. In this article, you will learn what anodized aluminum sheet is, how it works, and why it adds lasting value across many applications.

An anodized aluminum sheet is aluminum that has been strengthened through an electrochemical anodizing process. During treatment, a dense aluminum oxide layer grows directly from the aluminum itself. It is not painted or coated on the surface, so it does not separate from the base metal during use.

This integrated structure explains why an anodized aluminum sheet feels solid, keeps a clean metallic look, and performs better over time. It protects the surface while preserving aluminum’s lightweight nature. In daily use and demanding environments, the material maintains appearance and function more reliably than untreated aluminum.From a practical perspective, this means fewer surface failures and more predictable performance. The anodized aluminum sheet handles exposure, handling, and long service cycles without frequent refinishing or repair.

The anodizing process uses controlled oxidation to enhance aluminum’s natural properties. The aluminum sheet enters an electrolyte bath and receives an electrical current. Oxygen reacts with the aluminum surface and forms a porous oxide layer. This layer grows evenly across the sheet and can later be sealed for protection.

Because the surface is porous before sealing, it accepts color and texture evenly. Once sealed, the oxide layer becomes hard and stable. This explains why anodized aluminum sheet does not peel, crack, or fade like painted surfaces.Main process stages include:

● Surface cleaning to remove oils and impurities

● Electrochemical oxidation to grow the oxide layer

● Optional coloring while pores remain open

● Sealing to lock in durability and stability

This controlled method ensures consistent quality and long-term reliability across the entire surface.

Comparing anodized aluminum sheet with regular aluminum helps clarify value and performance. Regular aluminum is lightweight and easy to form, but its surface offers limited protection against wear and corrosion. Anodized aluminum sheet improves surface strength while keeping aluminum’s natural advantages.

This difference matters in projects requiring both appearance and reliability. The anodized surface reduces maintenance needs and extends service life without adding weight or complexity.

Aspect | Regular Aluminum | Anodized Aluminum Sheet |

Surface Structure | Natural metal surface | Integrated oxide layer |

Corrosion Resistance | Limited | Strong and stable |

Scratch Resistance | Low | Significantly improved |

Expected Lifespan | Shorter | Longer |

When you compare anodized aluminum sheet with regular aluminum, the key differences appear in protection, durability, and long-term value. Regular aluminum is lightweight and easy to form, but its surface remains directly exposed to air, moisture, and daily contact. Over time, this exposure can lead to corrosion, surface wear, and visual degradation.

An anodized aluminum sheet adds a protective oxide layer that becomes part of the metal surface. This layer strengthens performance without changing aluminum’s natural advantages. It helps the material maintain both function and appearance over extended use.Key differences customers usually consider include:

● Corrosion resistance is much stronger on anodized aluminum sheet

● Surface hardness increases, reducing scratches and abrasion

● Appearance remains stable under frequent handling

● Lifespan extends compared to untreated aluminum

From a practical view, anodized aluminum sheet reduces maintenance needs and replacement frequency. It performs reliably in applications where durability, consistent appearance, and long service life are important.

The anodic oxide layer acts as a natural shield for the aluminum surface. It separates the metal from moisture, oxygen, and airborne pollutants. This protection allows an anodized aluminum sheet to perform reliably in both indoor and outdoor environments. Even under long-term exposure, the surface remains stable and does not rust or break down easily.

If you work on projects exposed to humidity, rain, or changing temperatures, this property becomes especially important. It helps reduce long-term risk and keeps structures or products looking consistent over time. The material supports durability without frequent repairs or surface treatments.Key benefits customers often notice include:

● Strong resistance to oxidation and corrosion over extended use

● Stable appearance under sunlight, moisture, and air exposure

● Reduced need for replacement, repainting, or refinishing

An anodized aluminum sheet has a significantly harder surface than untreated aluminum. The anodizing process increases surface hardness by forming a dense oxide layer. This layer resists daily abrasion, repeated contact, and light impact during use.

In areas where surfaces are touched often or remain highly visible, this hardness helps maintain appearance. Fewer scratches appear over time, and the surface stays clean and professional. It also protects detailed finishes, allowing textures and patterns to last longer.This property adds clear value in applications such as:

● Decorative panels and engraved nameplates

● Consumer-facing products requiring a refined look

● High-contact architectural surfaces like trims and panels

Anodized aluminum sheet contains no paint or organic surface coatings. Because of this, it does not ignite easily and does not release toxic gases when exposed to high temperatures. The aluminum structure and oxide layer remain stable under heat.

This behavior makes anodized aluminum sheet suitable for environments where safety standards matter. It supports fire-conscious design choices without adding complexity or additional treatments.Safety-related advantages include:

● Non-combustible surface behavior under heat

● No melting, peeling, or burning coatings

● Better alignment with fire safety expectations

The sealed anodized surface resists fingerprints, stains, and general surface contamination. Dirt and residue do not bond easily to the oxide layer. Routine cleaning usually requires only water and mild soap, without harsh chemicals.

For long-term use, this means less maintenance effort and more predictable appearance. It also helps anodized aluminum sheet remain clean and presentable in high-traffic or highly visible areas.

Maintenance Aspect | Customer Benefit |

Fingerprint Resistance | Cleaner surface appearance |

Cleaning Method | Simple and non-abrasive |

Stain Resistance | Reduced surface marks |

Long-Term Care | Lower maintenance cost |

When you evaluate an anodized aluminum sheet, thickness and oxide film depth often come first. These specifications directly affect durability, wear resistance, and suitability for different environments. Thinner oxide layers perform well indoors, while thicker layers handle outdoor exposure, humidity, and repeated contact more effectively.

From a practical view, selecting the correct range helps balance performance, cost, and appearance. It also prevents over-engineering or under-specifying materials. When the anodized aluminum sheet matches real project conditions, long-term reliability improves and maintenance needs drop.How different ranges influence performance in real use:

● Thinner films support decorative and interior applications

● Medium films improve scratch resistance for frequent handling

● Thicker films increase weather resistance and service life

● Proper matching reduces maintenance and replacement needs

Oxide Film Range | Typical Use Focus | Performance Impact |

Light range | Indoor decorative panels | Clean look, basic protection |

Medium range | General-purpose applications | Balanced durability |

Thick range | Outdoor or harsh environments | Maximum wear resistance |

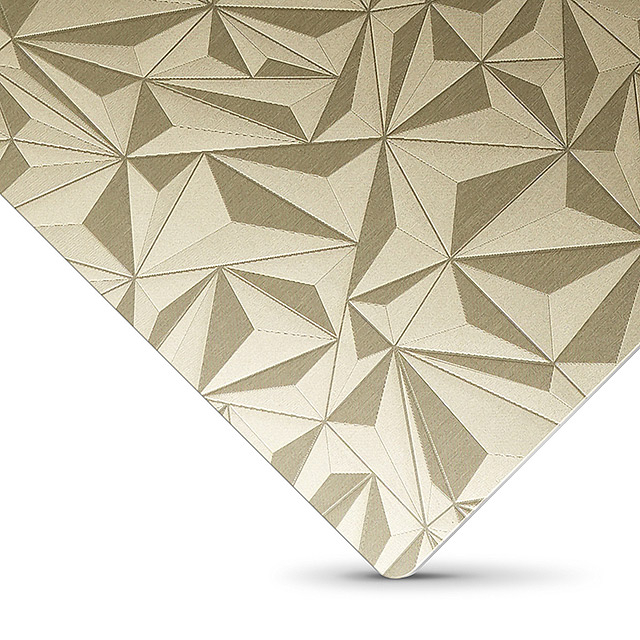

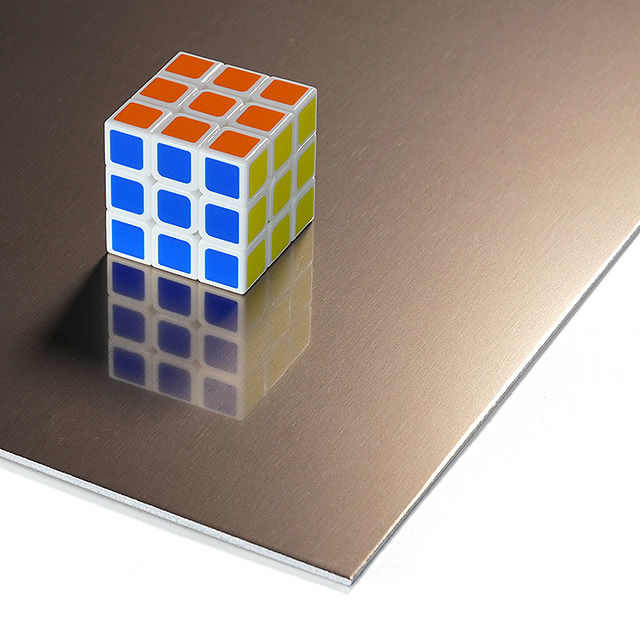

Surface finish shapes how an anodized aluminum sheet looks and feels during daily use. Some finishes highlight texture, while others emphasize reflection or detail. These choices affect both appearance and practicality.

Each finish interacts differently with light, touch, and cleaning. This flexibility allows anodized aluminum sheet to follow modern design trends while meeting functional needs. Designers often select finishes based on visibility, contact level, and desired visual impact.Popular finish options and what they offer in practice:

● Brushed finishes create a modern, directional texture

● Engraved surfaces support logos, patterns, and identification

● Matte finishes reduce glare and soften reflections

● Bright finishes enhance metallic shine and visual impact

These finishes also influence how fingerprints, scratches, and wear appear over time. That detail matters for visible surfaces and high-touch areas.

Color anodizing allows anodized aluminum sheet to combine durability and design freedom. During anodizing, the oxide layer remains porous before sealing. Pigments enter these pores and lock in once sealed.

This process ensures colors stay stable and do not peel or flake. They become part of the surface instead of sitting on top. Color options support branding, decoration, and functional color coding across many applications.Why buyers prefer anodized color finishes in long-term projects:

● Colors resist fading under sunlight

● Surfaces maintain a metallic feel

● Finishes stay consistent across large areas

● Long-term appearance remains reliable

Anodized aluminum sheet is widely used in architectural and interior design projects because it balances visual appeal and long-term performance. It delivers a clean metallic look while handling daily exposure to light, air, and human contact. Designers and builders value how it maintains appearance without demanding frequent maintenance.

Its surface stability makes it suitable for both decorative features and functional building elements. The material performs well in modern designs where consistency and durability matter. It also supports large surfaces without visible aging over time.Common architectural uses include:

● Wall panels and ceiling systems for commercial and residential spaces

● Interior and exterior signage requiring long-term clarity

● Decorative facades, trims, and architectural accents

In industrial environments, anodized aluminum sheet provides reliable surface protection while remaining lightweight. The hardened oxide layer improves resistance to wear, corrosion, and handling damage during operation and maintenance. This makes it suitable for components exposed to repeated contact or challenging conditions.

Manufacturers choose it for equipment where predictable performance and long service life matter more than surface decoration. It helps reduce downtime and supports consistent quality in industrial systems.Typical industrial uses involve:

● Machinery covers and protective housings

● Equipment enclosures in controlled or exposed environments

● Precision components and functional panels

Application Area | Why Anodized Aluminum Sheet Works |

Machinery parts | Improved wear resistance |

Enclosures | Strong corrosion protection |

Precision panels | Stable dimensions and surface |

Anodized aluminum sheet also plays a key role in consumer products and custom projects. Its refined appearance, light weight, and durability support both large-scale production and customized fabrication. The material adapts easily to different designs without compromising reliability.

For consumer-facing products, design flexibility matters. Engraving and color anodizing help products stand out while keeping surfaces durable and easy to maintain.Common consumer-focused applications include:

● Household appliances and electronic housings

● Furniture accents, panels, and decorative elements

● Nameplates and custom engraved items

● Decorative and functional accessories

This article explains what an anodized aluminum sheet is and how it gains durability through anodizing. It highlights corrosion resistance, surface hardness, color stability, and easy maintenance. These features support use across architecture, industry, and consumer products. Anodized aluminum sheet offers long service life and design flexibility. Anlv New Materialdelivers anodized aluminum sheet solutions that focus on performance, customization, and reliable manufacturing value.

A: An anodized aluminum sheet is aluminum treated to form a hard, protective oxide surface.

A: The anodized aluminum sheet has an oxide layer that resists corrosion and wear.

A: Anodized aluminum sheet is used in buildings, machinery, electronics, and decorative parts.

A: Anodized aluminum sheet offers good value due to long life and low maintenance.

A: An anodized aluminum sheet cleans easily using water and mild soap.