- Home

- Products

- OEM&ODM Services

- About

- Applications

- Resources

- Blogs

- Contact

Views: 0 Author: Site Editor Publish Time: 2026-02-10 Origin: Site

Cutting a 5 pack anodized aluminum sheet looks simple, but mistakes ruin the surface fast. Many users struggle with scratches, heat marks, and uneven edges. In this article, you will learn how to cut anodized aluminum sheet packs correctly, choose tools wisely, and protect finish quality from start to end.

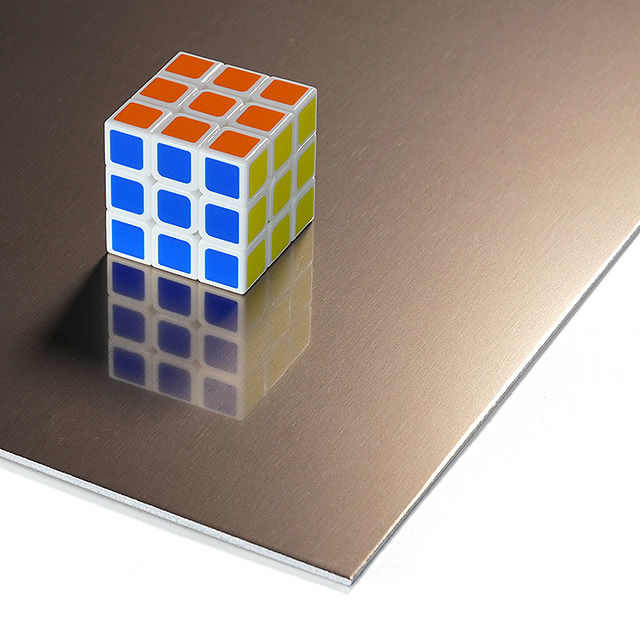

An anodized aluminum sheet is not just regular aluminum with color on top. The anodizing process creates a hard oxide layer that becomes part of the metal itself. This layer improves surface hardness, increases corrosion resistance, and gives the sheet a clean, finished appearance.

When cutting a 5 pack anodized aluminum sheet, this hardened surface reacts differently to blades and heat compared to raw aluminum, so technique matters more. It resists scratches better, but once damaged, it cannot self-repair like paint or coatings.

Key performance traits that affect cutting include:

● Higher surface hardness, which increases blade wear if tools are poorly selected.

● Strong corrosion resistance, which must be preserved by minimizing heat buildup.

● A decorative finish that requires protection during clamping and cutting.

5 pack anodized aluminum sheets are typically supplied in controlled thickness ranges to support both industrial and decorative applications. Thickness directly affects tool selection, cutting speed, and whether sheets can be stacked safely during processing. Thinner sheets cut faster but shift more easily, while thicker sheets require more power and careful heat control to protect the anodized surface.

Below is a practical overview of common thickness ranges and how they influence cutting decisions:

Thickness Range | Typical Use Scenarios | Cutting Considerations |

0.5–1.0 mm | Signage, nameplates, panels | Light tools, surface protection critical |

1.5–2.0 mm | Enclosures, decorative panels | Stable cutting, moderate power tools |

2.5–3.0 mm | Architectural, industrial parts | Slower feed, heat management needed |

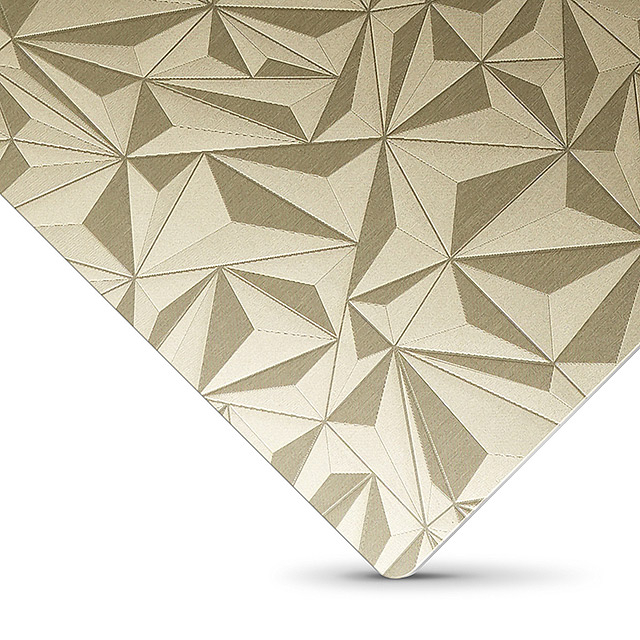

Surface finish also plays a major role. Brushed anodized aluminum sheets highlight directional texture, so scratches stand out if clamping is careless. Engraved finishes add depth and visual detail, but they demand even pressure during cutting to avoid edge chipping. Sleek or smooth finishes are easier to protect, yet they still require proper blade alignment to maintain clean edges.

Typical use scenarios include:

● Decorative architectural panels that demand clean, visible edges.

● Industrial covers where dimensional accuracy matters more than appearance.

● Custom engraved components where surface detail must remain intact.

Hand tools work best when the anodized aluminum sheet is thin and the cut length stays short. Tin snips and hacksaws fit small workshops or on-site adjustments, especially when power access feels limited. They give strong control, yet they struggle when five sheets stack together.

The anodized layer adds surface hardness, so blades dull faster and edges can deform if pressure increases too much.

For practical use, they make sense in specific situations:

● Tin snips suit thin sheets for short straight or gentle curved cuts, but they can bend stacked sheets.

● Hacksaws handle small straight cuts, yet the process stays slow and edges often need extra finishing.

● Both tools require careful clamping, or sheets shift and scratch during cutting.

Power tools offer speed, consistency, and cleaner edges when cutting anodized aluminum sheet packs. Circular saws and jigsaws handle stacked sheets far better, especially when paired with blades designed for non-ferrous metals.

Blade choice matters because anodized surfaces react badly to heat and vibration. A poor blade causes discoloration or chipped edges, even if the cut looks straight.

Common power tools and their roles appear below:

Power Tool | Best Use | Key Notes |

Circular saw | Long straight cuts | Carbide blade, steady feed |

Jigsaw | Curves and cutouts | Fine-tooth metal blade |

CNC router | Repeated precision cuts | Consistent edges, low error |

Choosing tools becomes easier when thickness and cut type guide the decision. Thin sheets allow flexibility, while thicker anodized aluminum sheet packs demand more power and control. Straight cuts reward stable tools, while curves need maneuverability. Overthinking often leads to mistakes, so a simple matching approach works best.

Use this quick guide when selecting tools:

● Thin sheets under 1.5 mm: jigsaw or snips for short cuts, light feed pressure.

● Medium thickness around 2.0 mm: circular saw for straight lines, jigsaw for curves.

● Thicker sheets above 2.5 mm: circular saw or CNC methods, slower speed. Matching the tool to the job keeps the anodized layer intact and reduces rework time.

Preparation sets the outcome before any blade touches metal. Measure carefully, mark clearly, and align all five sheets so edges sit flush. Keep the protective film on each anodized aluminum sheet during marking and clamping. It shields the surface from scratches and clamp pressure, which matters more when sheets stack together.

Preparation steps to follow include:

● Use a fine marker or scribe for visible cut lines.

● Clamp sheets tightly on both sides of the cut to stop vibration.

● Support the underside so the blade exits cleanly. This setup helps every sheet in the pack cut evenly, not just the top one.

Cutting technique controls heat, surface quality, and edge consistency. Slow, steady feeding keeps friction low and prevents aluminum from melting onto blades. Light lubrication helps cooling and improves edge finish, especially during longer cuts. Rushing creates heat marks that permanently damage the anodized layer.

Good cutting habits include:

● Start the tool before contacting the sheet.

● Maintain even pressure and constant speed.

● Pause if chips build up or the blade heats. These habits protect the anodized aluminum sheet finish and extend blade life.

Straight cuts and curves demand different handling styles. Straight lines favor rigid tools like circular saws, guided by a straight edge. Curves rely on jigsaws, which allow gradual turns without forcing the blade. For stacked sheets, curves require slower movement to keep all layers aligned.

Below is a simple comparison:

Cut Type | Recommended Tool | Technique Focus |

Straight | Circular saw | Guide rail, steady feed |

Curved | Jigsaw | Slow turns, blade control |

Understanding this difference prevents uneven edges and surface damage across the pack.

Safety stays essential when cutting multiple anodized aluminum sheets at once. Sharp edges form instantly, and stacked sheets amplify risk. Gloves protect hands during handling, while eye protection shields against metal chips. A stable workspace reduces sudden movement, which often causes slips or blade binding.

Key safety habits include:

● Wear gloves, goggles, and hearing protection.

● Keep hands away from blade exit zones.

● Deburr edges before moving finished sheets. These practices keep the process controlled while maintaining the quality of every anodized aluminum sheet in the pack.

Finishing starts right after the cut ends, not later. Every anodized aluminum sheet leaves the blade with sharp burrs that feel small yet cut easily. We remove them gently, so the anodized layer stays intact and corrosion resistance remains strong. Light pressure matters more than speed, because aggressive grinding damages edges permanently and exposes raw aluminum.

Safe finishing methods focus on control and consistency:

● Hand deburring tools glide along edges and remove burrs without biting into anodizing.

● Fine-grit sandpaper smooths edges when used lightly and evenly.

● Soft files work only when strokes stay one-directional and minimal. This approach keeps the edge clean and uniform across all five sheets, not just the top one.

Finishing Tool | Best Use Case | Surface Risk Level |

Hand deburrer | Clean straight edges | Very low |

Fine sandpaper | Light edge smoothing | Low |

Metal file | Thick sheet edges | Medium |

Problems often appear when small details get overlooked during setup or cutting. Blade clogging is one of the most common issues. It happens when cutting speed stays too high or lubrication is missing, causing aluminum to soften and stick to blade teeth. Once this starts, friction rises quickly, heat increases, and the anodized aluminum sheet surface becomes vulnerable to burn marks. These marks look minor at first, but they permanently damage the anodized layer and reduce corrosion resistance.

Uneven edges create another frequent challenge. Even when clamps feel secure, stacked sheets can shift slightly under vibration. That small movement leads to stepped edges, where each sheet finishes at a different line. This problem becomes more visible during installation, especially when sheets must align visually. Surface scratches also occur more often than expected. Tool bases, clamps, or guide rails sliding during cutting can drag across the anodized surface, leaving marks that cannot be polished out.

Typical issues users face include:

● Blade loading caused by excessive speed, dull blades, or no lubrication, leading to rough cuts.

● Misaligned sheets creating uneven edges across the pack, increasing finishing time.

● Scratches from clamps or tool bases moving during cutting, damaging appearance.

Safety stays essential when cutting multiple anodized aluminum sheets at once. Sharp edges form instantly, and stacked sheets amplify risk during handling and movement. Gloves protect hands from cuts, while eye protection shields against flying metal chips. A stable, well-lit workspace reduces sudden movement, which often causes slips, blade binding, or uneven cuts. Proper positioning helps maintain control throughout the process.

Key safety habits include:

● Wear gloves, goggles, and hearing protection at all times.

● Keep hands away from blade exit zones and cutting paths.

● Deburr edges before moving finished sheets to avoid injury. These practices keep the process controlled, reduce accidents, and maintain the quality of every anodized aluminum sheet in the pack.

Some projects go beyond the comfort zone of standard workshop tools. Thicker anodized aluminum sheet packs require more power and control, while complex shapes demand precision that hand tools struggle to deliver. Tight tolerances also increase the risk of material loss if mistakes occur. In these situations, outsourcing cutting saves time and protects material value.

Professional cutting makes sense when:

● Sheet thickness exceeds common shop tool limits.

● Engraved or decorative surfaces require flawless edges.

● Large batches demand identical results every time. Industrial cutting methods offer repeatability and accuracy that manual setups cannot always achieve.

This article explains how to cut 5 pack anodized aluminum sheets safely and cleanly. It covers tool selection, cutting methods, surface protection, and finishing steps. Anlv New Material supplies consistent anodized aluminum sheets that support stable cutting, reliable results, and efficient processing for different applications.

A: The safest way is using proper metal blades, steady feed speed, and firm clamping to protect each anodized aluminum sheet.

A: Yes, stacking works well if all anodized aluminum sheet layers align tightly and vibration stays controlled.

A: Burn marks appear when heat builds too fast, damaging the anodized aluminum sheet surface.

A: A circular saw or jigsaw using non-ferrous blades produces cleaner edges on anodized aluminum sheet cuts.

A: Professional cutting helps when anodized aluminum sheet thickness, precision, or batch size increases.