- Home

- Products

- OEM&ODM Services

- About

- Applications

- Resources

- Blogs

- Contact

Views: 0 Author: Site Editor Publish Time: 2025-07-04 Origin: Site

In modern industries, the demand for high-performance, aesthetically pleasing metal surfaces has given rise to specialized surface treatment technologies. One standout solution is the Electrolytically Colored Aluminum Plate, a product that combines strength, corrosion resistance, and rich metallic tones. Unlike organic dyes, electrolytic coloring embeds inorganic metal-based pigments into anodized aluminum for unmatched durability and colorfastness. At Guangdong Anlv New Material Co., Ltd., we manufacture precision anodized and electrolytically colored aluminum plates to meet the high-performance needs of architecture, electronics, and industrial applications. In this article, we’ll explore how electrolytic coloring works, what it offers, and why it may be the right choice for your next project.

Electrolytic coloring is a post-anodizing treatment that infuses the porous aluminum oxide layer with metal ions using alternating current and a specialized electrolyte solution. Commonly, this electrolyte contains tin, cobalt, or nickel salts. During this process, the metal ions are deposited into the oxide layer, creating a metallic, lightfast finish.

In contrast, traditional dyeing uses organic pigments introduced into the anodized layer, followed by sealing. These dyes rely on absorption into the pores and are more prone to fading over time—especially under UV exposure or in harsh outdoor conditions.

When it comes to longevity, electrolytically colored aluminum plates significantly outperform dyed surfaces. The metallic colors created via electrolytic methods are highly stable under sunlight, heat, and chemical exposure. They retain their depth and hue over many years, even in exterior environments.

For industries that demand fade resistance, uniformity, and robust color performance—such as facade systems or control panel labeling—electrolytic coloring offers a dependable solution. At Guangdong Anlv, our production line uses advanced AC control and tin-based electrolytes to ensure uniform, rich, and long-lasting finishes.

The production of electrolytically colored aluminum plates involves a sequence of tightly controlled steps:

Surface Preparation: The aluminum plate is cleaned and degreased to remove contaminants and ensure an even surface.

Anodizing: The plate is anodized in a sulfuric acid bath to produce a porous oxide layer of controlled thickness.

Electrolytic Coloring: The plate is then submerged in a metal salt electrolyte and subjected to an alternating current. Metal ions are deposited in the oxide layer’s pores, creating a uniform metallic color.

Sealing: Finally, the plate is sealed—usually in hot deionized water—to close the pores and lock in the metal ions, completing the process.

Each step is carefully monitored to ensure adhesion, uniformity, and long-term durability. At Guangdong Anlv, we use automated lines and precision testing at every stage to deliver consistently high-quality anodized and electrolytically colored products.

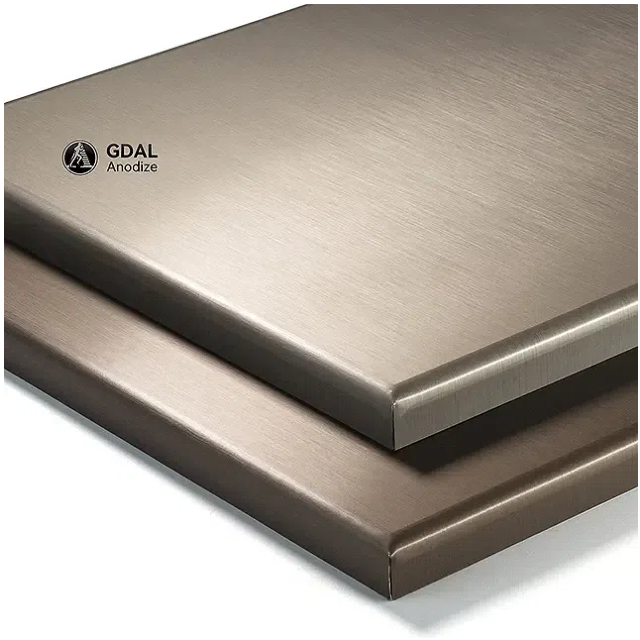

Electrolytic coloring creates sophisticated, professional-looking metallic finishes that are ideal for high-end product applications. Popular color options include:

Champagne: A light, elegant gold tone that complements architectural interiors.

Black: A deep, solid black with a metallic sheen—often used in electronics and signage.

Bronze: A rich, warm brown with excellent UV resistance, perfect for outdoor panels and trim.

These colors are not painted or printed but are integrated into the oxide layer itself, making them resistant to peeling, fading, or abrasion.

Advanced versions of electrolytic coloring may use interference effects—manipulating light and oxide thickness to produce unique iridescent appearances. While more technically demanding, this approach is growing in popularity for decorative applications where visual impact is a priority.

Our team at Guangdong Anlv can help you explore these custom solutions, depending on your design requirements and performance needs.

One of the strongest arguments in favor of electrolytically colored aluminum plates is their exceptional performance in outdoor environments. Organic dyes, while vibrant, often degrade in sunlight, especially after extended UV exposure. Electrolytic coloring, on the other hand, offers:

Superior UV stability

Minimal color shift over time

Better resistance to pollution, salt spray, and chemicals

For exterior cladding, signage, or marine applications, these benefits translate directly into a longer lifespan and better return on investment.

At Guangdong Anlv, we help clients select the appropriate anodizing and coloring system based on expected exposure conditions—whether indoors or in the toughest outdoor climates.

Electrolytically colored aluminum plates are widely adopted across multiple industries due to their combination of aesthetics and endurance:

Architecture: Window frames, curtain walls, wall panels, and roofing where consistent appearance and corrosion resistance are essential.

Signage: Directional and commercial signs that must retain visual clarity and color integrity over time.

Consumer Electronics: Device casings, laptops, and audio equipment that require a sleek, scratch-resistant finish.

Another important application is in industrial labeling and control systems, particularly photosensitive nameplates or panels. These plates are exposed to high light, heat, and potential chemical interactions. The stability of electrolytically colored finishes ensures labels remain legible and professional-looking even under heavy use.

At Guangdong Anlv, we work with clients from industrial automation, real estate development, and product manufacturing to deliver custom electrolytically colored aluminum products that meet exact specifications.

While electrolytic coloring offers many advantages, there are also technical considerations:

Alloy Compatibility: Not all aluminum alloys respond equally well to electrolytic coloring. The process works best on 5000- and 6000-series alloys.

Cost: Electrolytic coloring can be more expensive than traditional dyeing due to energy consumption and metal ion use.

Oxide Layer Thickness: Coloring quality depends on the anodic layer thickness—typically 15–25 microns for consistent results.

Angle-Dependent Appearance: Metallic tones may shift slightly depending on viewing angle, which can be either an advantage or a design challenge.

Our team at Guangdong Anlv New Material Co., Ltd. provides consulting to help customers navigate these technical factors and determine the right finishing process for their application.

Electrolytically colored aluminum plates are an ideal solution when appearance, durability, and performance are non-negotiable. From architectural facades to durable nameplates and high-end electronics, the benefits of electrolytic coloring are clear: fade resistance, a rich metallic finish, and long-term value. If you need an anodized aluminum product that performs beautifully under pressure—both literal and environmental—electrolytic coloring is the option to consider.

At Guangdong Anlv New Material Co., Ltd., we combine cutting-edge anodizing processes with customer-specific customization to deliver top-grade electrolytically colored aluminum plates. Whether you need black, bronze, or champagne tones—or you’re seeking guidance on the right finish—our expert team is here to support your success.

Contact us today to learn more about our electrolytic coloring solutions and how we can help elevate your next project with materials engineered to perform.