- Home

- Products

- OEM&ODM Services

- About

- Applications

- Resources

- Blogs

- Contact

Views: 0 Author: Site Editor Publish Time: 2025-07-04 Origin: Site

In today’s fast-evolving world of architecture, electronics, consumer goods, and industrial components, material choice has become more crucial than ever. Among a wide variety of materials, anodized aluminum has gained significant attention for its durability, aesthetics, and adaptability across industries. But what exactly is anodized aluminum, and why is it considered a premium solution? This article explores its meaning, the science behind the process, and why companies like Guangdong Anlv New Material Co., Ltd., a leading manufacturer of anodized aluminum coils, continue to innovate in this space to meet growing market demand.

Anodized aluminum is not a painted or coated surface—rather, it is the result of a controlled electrochemical process that enhances the natural oxide layer of the aluminum substrate. During this process, the aluminum piece is submerged in an acid electrolyte bath and subjected to an electric current. This causes oxygen ions from the electrolyte to combine with the aluminum atoms on the surface, forming aluminum oxide.

The resulting oxide layer is not applied externally but grown from within the aluminum itself. It is hard, porous, and corrosion-resistant. Unlike surface coatings that may peel or chip over time, this layer becomes part of the metal, providing long-lasting protection and finish.

A key distinction between anodizing and conventional coatings lies in how the protective layer is formed. In painting or plating, the protective material is layered on top of the substrate and may eventually degrade or detach due to external factors. In contrast, the anodizing process transforms the outer layer of the aluminum itself, resulting in a much more durable and integrated finish.

Additionally, anodized aluminum retains a metallic appearance, often preferred for its modern, industrial aesthetic. The oxide layer is also porous initially, allowing for dyeing and color customization that become locked in during the sealing phase—another feature that differentiates it from superficial coatings.

Aluminum naturally forms a thin oxide layer when exposed to air, which provides some degree of protection. However, this native oxide is often inconsistent and too thin for demanding applications. The anodizing process artificially thickens and stabilizes this layer, creating a uniform and robust anodic oxide that offers significantly enhanced performance characteristics, including improved corrosion and wear resistance.

This makes aluminum an excellent candidate for anodizing—its natural tendencies are simply amplified through technology.

Not all metals are suitable for anodizing, but aluminum's unique chemical and physical properties make it especially compatible. Its various alloy forms respond well to anodizing, allowing manufacturers to fine-tune the process according to the desired strength, flexibility, or aesthetic effect.

For instance, 5000 and 6000 series aluminum alloys are commonly used in architectural panels and consumer electronics, thanks to their optimal anodizing behavior. This versatility allows manufacturers like Guangdong Anlv New Material Co., Ltd. to offer a wide range of anodized aluminum solutions tailored to specific industry needs, from brushed finishes to mirror or patterned surfaces.

Before anodizing begins, aluminum surfaces must be thoroughly cleaned to remove any grease, oxide residue, or contaminants. This is typically done using a combination of mechanical and chemical processes such as alkaline cleaning, acid etching, and rinsing.

A smooth, clean surface ensures that the anodic layer forms evenly and adheres properly. In some cases, mechanical polishing or brushing may be performed beforehand to achieve specific surface textures that complement the final anodized appearance.

The core of the anodizing process involves submerging the cleaned aluminum in an acid electrolyte bath—commonly sulfuric acid—while passing an electric current through it. The aluminum acts as the anode, and a cathode (usually lead or stainless steel) completes the circuit.

Voltage and temperature are carefully regulated to control the thickness and structure of the oxide layer. Thicker coatings are ideal for outdoor and industrial use, while thinner coatings are suited for decorative applications.

Guangdong Anlv New Material Co., Ltd. employs precise quality control and advanced automation in this stage to ensure consistent product results, especially for large-scale aluminum coil production.

After anodizing, the aluminum is still porous and must be sealed to prevent corrosion and lock in any optional coloring. Sealing is usually performed using hot water, steam, or nickel acetate solutions, which close the pores and stabilize the oxide layer.

If a colored finish is desired, dyeing takes place before sealing. This step allows for an impressive range of colors—black, bronze, gold, blue, and more—all resistant to fading due to the dye being embedded beneath the surface.

One of the most attractive features of anodized aluminum is its enhanced durability. The anodic layer significantly improves the surface’s hardness, making it more resistant to scratches, abrasion, and environmental wear. This makes it ideal for exterior panels, signage, kitchen appliances, and mobile devices.

Moreover, anodized aluminum exhibits exceptional corrosion resistance. Even in high-humidity or marine environments, it maintains its integrity without requiring additional coatings or frequent maintenance.

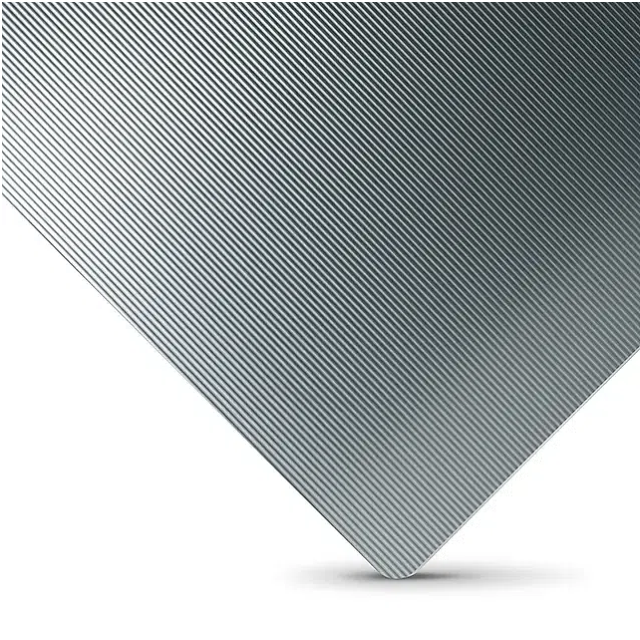

Beyond functional benefits, anodized aluminum is celebrated for its refined, high-end appearance. The process can yield various textures—from matte to glossy—and can be further customized through brushing, sandblasting, or polishing.

The coloring potential also gives designers and manufacturers creative flexibility. Whether it’s the luxurious sheen of mirror aluminum or the minimalist elegance of satin black, anodized finishes elevate the visual appeal of any product.

Guangdong Anlv New Material Co., Ltd. offers a wide range of finishes, allowing customers to choose textures and colors that align with brand identities or product design goals.

Understanding what anodized aluminum is—and what it can offer—empowers designers, manufacturers, and end users to make smarter material decisions. Whether you’re looking for a durable solution for building cladding, a stylish finish for consumer electronics, or a corrosion-resistant material for industrial use, anodized aluminum stands out as a leading option. With advanced manufacturing capabilities and a commitment to customization, Guangdong Anlv New Material Co., Ltd. is proud to serve global customers with premium anodized aluminum products designed for lasting impact.

Contact us today to learn more about our anodized aluminum coils and find out how we can support your project with expert solutions and consistent quality.