- Home

- Products

- OEM&ODM Services

- About

- Applications

- Resources

- Blogs

- Contact

Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

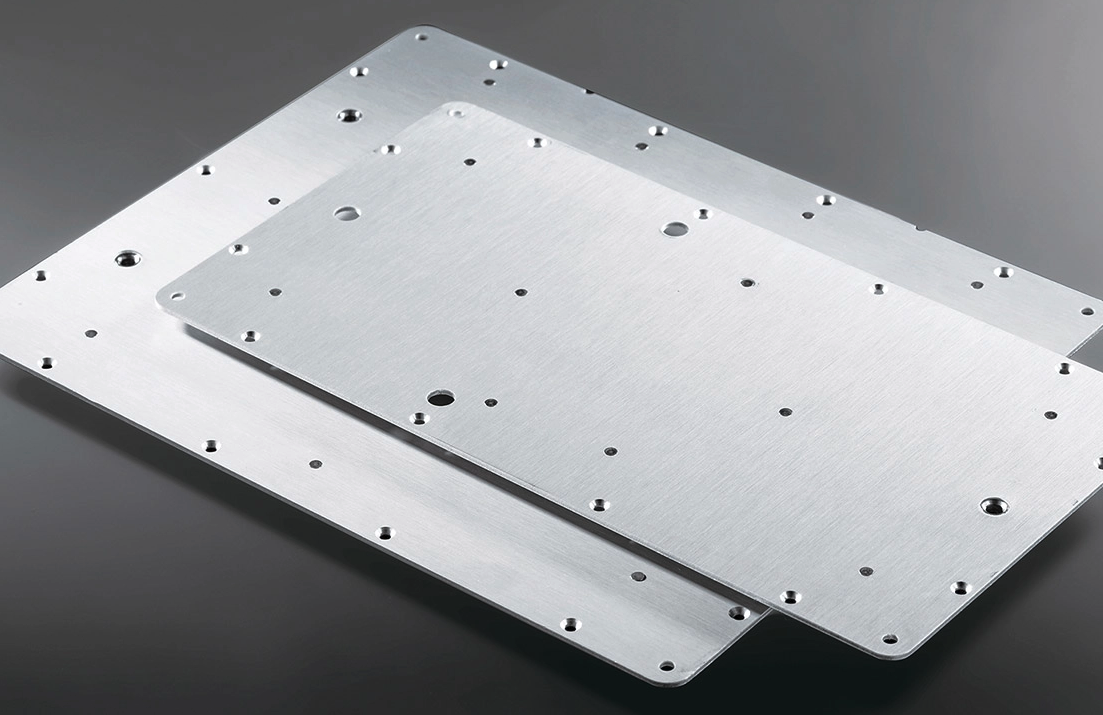

In the dynamic world of metal finishing, the quest for enhancing the durability and longevity of metal products is a constant pursuit. At Guangdong Anlv New Material Co., Ltd., we specialize in providing high-quality anodized aluminum products that meet the demands of modern industries. Batch anodizing, a specialized electrochemical process, creates a durable, corrosion-resistant oxide layer on aluminum surfaces. This process is crucial for enhancing the longevity and performance of metal products in various industrial and consumer applications. The growing demand for anodized aluminum in construction, automotive, aerospace, and electronics underscores the importance of understanding how batch anodizing works and why it’s a preferred surface treatment.

Anodized Aluminum is aluminum whose surface has been converted into a controlled, thicker aluminum oxide layer through an electrochemical process. This oxide layer is integral to the metal, not a paint or coating, and provides superior corrosion and wear resistance. The anodic film can be porous before sealing. After sealing, it becomes hard, stable, and less reactive to the environment. These properties make it ideal for facades, curtain walls, consumer goods, and industrial parts.

Aluminum, while lightweight and versatile, is susceptible to corrosion in harsh environments and wear in high-use applications. Understanding these vulnerabilities is key to appreciating the benefits of anodizing. Aluminum’s natural oxide layer offers some protection, but it is not sufficient for industrial applications where exposure to moisture, salts, and pollutants is common. Anodizing enhances this natural protection, making aluminum more durable and long-lasting.

Pre-treatment: Cleaning, degreasing, and etching to prepare the surface.

Anodizing: Electrochemical oxidation in an acid electrolyte bath.

Coloring (optional): Dyeing or electrolytic coloring for aesthetic enhancement.

Sealing: Closing the pores to enhance corrosion resistance.

Batch anodizing involves treating multiple parts at once in controlled tanks. This method allows for greater flexibility and customization, making it ideal for a variety of applications, from architectural components to automotive parts.

Batch anodizing is ideal for specific, often complex, parts, while continuous (coil) anodizing is used for long sheets or coils. Batch anodizing offers greater flexibility and control over the process, allowing for customized dwell times and varied geometries. Continuous anodizing, on the other hand, is more suited for high-volume production runs where uniformity is key.

Batch anodizing requires specialized equipment, including tanks, racks, power supplies, and process control systems, to ensure consistent and high-quality results. Modern batch anodizing lines are equipped with advanced automation and monitoring systems to ensure precise control over the anodizing process, resulting in uniform and durable anodic layers.

The oxide layer acts as a physical barrier, preventing moisture, salt, and chemicals from reaching the aluminum surface, thereby reducing corrosion. This layer is highly durable and resistant to environmental factors, making it ideal for outdoor applications where exposure to harsh conditions is common.

Anodizing significantly increases the surface hardness of aluminum, making it more resistant to abrasion and wear in high-contact areas. The hard oxide layer provides superior protection against scratches and other forms of mechanical wear, ensuring that the aluminum maintains its integrity over time.

Anodized aluminum exhibits excellent resistance to UV damage and fading, making it ideal for outdoor applications such as architectural facades and transportation components. The anodic layer protects the aluminum from the harmful effects of UV radiation, ensuring that the material maintains its appearance and performance over time.

Batch anodizing stands out as a superior metal finishing option, offering a range of benefits that make it a preferred choice for a wide variety of applications. Here’s a deeper dive into why batch anodizing is often the best choice:

One of the key advantages of batch anodizing is its exceptional longevity. The anodic oxide layer created during the anodizing process is highly durable and resistant to wear and environmental factors. This layer is chemically bonded to the aluminum, making it an integral part of the material itself. As a result, anodized aluminum products can maintain their appearance and performance for many years without significant degradation. This long lifespan translates into reduced replacement costs and less frequent maintenance, making batch anodizing a cost-effective solution in the long run.

Batch anodizing is an environmentally friendly process that aligns with modern sustainability goals. The process produces minimal waste and emissions, making it a preferred choice for environmentally conscious manufacturers. The anodic layer is created through an electrochemical process that does not involve harmful chemicals or solvents, reducing the environmental impact of the finishing process. Additionally, the anodized aluminum can be recycled without losing its properties, further enhancing its eco-friendly nature.

When additional coatings or adhesives are required, anodized aluminum provides an excellent base. The anodic layer enhances the adhesion of paints, coatings, and adhesives, ensuring that they bond more effectively and last longer. This is particularly beneficial in applications where multiple layers of protection are needed, such as in marine or industrial environments. The improved adhesion ensures that the additional coatings remain intact, providing long-term protection and durability.

Thicker anodizing layers provide better protection for marine and industrial applications where corrosion resistance is critical. Typical specification ranges are 5–25 microns for decorative finishes, 15–50 microns for protective applications, and up to 100+ microns for heavy-duty uses.

The purity and composition of the aluminum alloy can significantly affect the quality and durability of the anodized finish. Different alloys offer varying levels of corrosion resistance and mechanical strength, making it important to choose the right alloy for the specific application.

Humidity, salt, and pollutants in the environment can influence the longevity of anodized aluminum, making proper anodizing crucial for long-term performance. Anodized aluminum is particularly effective in environments with high UV exposure, moisture, and temperature variations.

Routine cleaning and avoiding abrasive damage are essential for maintaining the integrity of the anodized surface. Proper maintenance practices can significantly extend the lifespan of anodized aluminum products, ensuring they remain in optimal condition over time.

| Factors Affecting Performance | Details |

|---|---|

| Anodizing Thickness | 5–25 microns (decorative), 15–50 microns (protective), 100+ microns (heavy-duty) |

| Aluminum Alloy Composition | Purity and alloy composition affect corrosion resistance and mechanical strength |

| Environmental Conditions | Humidity, salt, pollutants, UV exposure, moisture, and temperature variations |

| Maintenance Practices | Routine cleaning, avoiding abrasives to maintain surface integrity |

Batch anodized aluminum is widely used in architectural applications such as curtain walls, window frames, and facade panels due to its durability and aesthetic appeal. The hard, corrosion-resistant surface of batch anodized aluminum makes it ideal for exterior cladding, ensuring that buildings maintain their appearance over time.

In the automotive and aerospace industries, batch anodizing is used for engine components, trim, and structural parts, providing both corrosion protection and wear resistance. The lightweight and durable nature of anodized aluminum makes it a preferred material for these industries, where performance and reliability are paramount.

Batch anodizing is ideal for electronic casings, heat sinks, and device housings, offering protection against wear and environmental factors. The anodic layer enhances the durability of aluminum components, ensuring they can withstand the rigors of daily use.

Marine applications, including boat parts, docks, and offshore structures, benefit from the corrosion resistance provided by batch anodizing. The anodic layer protects against saltwater corrosion, ensuring that marine components remain functional and durable over time.

Batch anodized aluminum is used in a variety of consumer goods, including kitchenware, furniture hardware, and sports equipment, due to its durability and aesthetic appeal. The anodic layer enhances the appearance and longevity of these products, making them more resistant to wear and environmental factors.

Choosing an experienced anodizing service provider ensures high-quality results and adherence to industry standards. A reliable partner will offer consistent quality, customization options, and the ability to handle complex geometries and varied production runs.

Different applications may require different types of anodizing, such as Type II for decorative purposes or Type III for hard anodizing. Understanding the specific needs of your application will help you choose the right type of anodizing to maximize durability and performance.

In some cases, combining anodizing with other protective coatings can enhance the overall durability and performance of the metal. This can be particularly useful in applications where additional protection against wear or environmental factors is required.

Regular inspections can help identify and address any signs of wear or damage early, ensuring the longevity of the anodized surface. Early detection and repair can prevent minor issues from becoming major problems, extending the lifespan of the product.

While aluminum is the most commonly anodized metal, other metals like titanium and magnesium can also be anodized.

Anodized aluminum can last for decades with proper maintenance, making it a highly durable choice.

Minor damage can be repaired, but significant damage may require re-anodizing the entire part.

Yes, batch anodizing is highly suitable for small parts and complex geometries.

Batch anodizing offers superior corrosion resistance and is more durable in harsh environments compared to powder coating.

Batch anodizing maximizes the durability of aluminum products by providing superior corrosion and wear protection. Its long-term benefits, eco-friendly nature, and versatility make it a valuable investment for industries seeking high-performance metal finishes. By choosing batch anodizing, you are not only investing in a superior finish but also contributing to a more sustainable future.