- Home

- Products

- OEM&ODM Services

- About

- Applications

- Resources

- Blogs

- Contact

Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

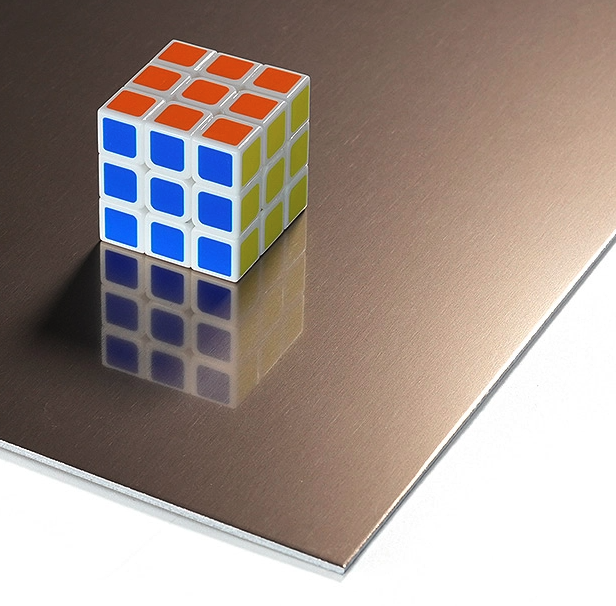

Anodizing aluminum is a transformative process that enhances both the durability and aesthetic appeal of aluminum products. Guangdong Anlv New Material Co., Ltd., a leading manufacturer of anodized aluminum plates, specializes in providing high-quality solutions for a variety of industries. The growing demand for anodized aluminum is driven by its superior corrosion resistance, wear resistance, and versatile aesthetic options. This comprehensive guide will walk you through the anodizing process, its benefits, and its applications.

Aluminum anodizing is an electrochemical process that creates a durable oxide layer on the surface of aluminum. This process transforms the metal’s surface, enhancing its durability and aesthetic properties. The oxide layer formed during anodizing is integral to the aluminum, providing superior protection against corrosion and wear.

The anodizing process involves submerging aluminum in an electrolyte solution and applying an electric current. This causes oxygen ions from the electrolyte to bond with aluminum atoms on the surface, forming a protective oxide layer. The thickness and properties of this layer can be controlled by adjusting the process parameters.

Anodizing creates a protective oxide layer that significantly enhances the corrosion resistance of aluminum. This makes it ideal for outdoor applications and harsh environments, such as architectural facades and marine components.

The oxide layer formed during anodizing is extremely hard, providing superior wear and scratch resistance. This makes anodized aluminum suitable for high-contact components and products that require long-term durability.

Anodizing offers a wide range of aesthetic options, including various colors, textures, and gloss levels. Guangdong Anlv New Material Co., Ltd. specializes in custom finishes, allowing clients to achieve their desired look.

Anodizing is an environmentally friendly process. The chemicals used are non-toxic, and aluminum is recyclable, making it a sustainable choice for modern manufacturing.

Type I anodizing uses chromic acid to create a thin oxide layer, typically between 0.00002 to 0.0001 inches thick. This method is ideal for applications requiring tight tolerances and is commonly used in aerospace components.

Type II anodizing is the most common method, using sulfuric acid to produce a thicker oxide layer (0.0001 to 0.001 inches). This method is known for its excellent wear resistance and is widely used in architectural and consumer applications.

Type III anodizing, also known as hardcoat anodizing, produces the thickest oxide layer (0.001 to 0.004 inches). This method is ideal for industrial applications where maximum wear resistance is required.

Decorative anodizing focuses on achieving visually appealing finishes, while functional anodizing prioritizes durability and performance. Guangdong Anlv New Material Co., Ltd. offers both types, tailored to meet specific client needs.

| Type | Description | Thickness Range | Application | Characteristics |

|---|---|---|---|---|

| Type I – Chromic Acid Anodizing | Uses chromic acid to create a thin oxide layer. | 0.00002 to 0.0001 inches | Aerospace components | Ideal for tight tolerances, excellent corrosion resistance |

| Type II – Sulfuric Acid Anodizing | Most common method using sulfuric acid for a thicker oxide layer. | 0.0001 to 0.001 inches | Architectural and consumer applications | Excellent wear resistance, wide range of colors |

| Type III – Hardcoat Anodizing | Produces the thickest oxide layer for maximum wear resistance. | 0.001 to 0.004 inches | Industrial applications | High durability, suitable for extreme conditions |

| Decorative vs. Functional Anodizing | Decorative focuses on aesthetics, functional on performance. | Varies by application | Custom solutions | Tailored to meet specific client needs |

To anodize aluminum, you will need a power supply, electrolyte solution, racks, dyes, and safety equipment. A detailed guide and support for setting up an anodizing station can be found in various resources online, ensuring you have all the necessary tools and materials to start the process.

Different aluminum alloys react differently to anodizing. Choosing the right alloy is crucial for achieving the desired finish and performance. Common alloys used for anodizing include 6061 and 7075, which offer excellent corrosion resistance and mechanical properties.

Handling acids and electricity requires careful safety measures. Proper ventilation, gloves, and eye protection are essential. Always ensure that your workspace is well-ventilated to avoid inhaling fumes from the chemicals used in the anodizing process.

The initial step in the anodizing process is surface cleaning, which is crucial for ensuring the optimal adhesion of the anodized layer. Use specialized cleaning agents and techniques to remove dirt, grease, and any existing oxide layers from the aluminum surface. This step is essential because any contaminants left on the surface can interfere with the anodizing process, leading to uneven coating or poor adhesion. Advanced cleaning methods ensure that the aluminum surface is pristine and ready for the next steps in the anodizing process.

After cleaning, the aluminum parts undergo etching and brightening processes. Etching creates a uniform surface finish by removing a thin layer of material, ensuring that the surface is free from imperfections and inconsistencies. Brightening enhances the reflective properties of the aluminum, giving it a shiny and polished appearance. State-of-the-art techniques achieve consistent and high-quality results, making the aluminum surface ready for the anodizing process.

Following etching, the desmutting process is carried out to remove any remaining impurities from the surface. This step is critical because it ensures that the surface is completely clean and free from any residual contaminants. Desmutting involves treating the surface with a neutralizing solution to eliminate any oxides or smut left behind after etching. This ensures that the surface is in perfect condition for the anodizing process, leading to a high-quality and durable finish.

Proper racking is essential for ensuring consistent electrical contact during the anodizing process. Use specialized racking systems to securely hold the aluminum parts. This ensures that each part is positioned correctly and that there is consistent electrical contact throughout the process. Proper racking is crucial for achieving uniform anodizing, as it ensures that the electric current is evenly distributed across the entire surface of the part.

The core of the anodizing process involves submerging the aluminum parts in an electrolyte solution and applying an electric current. This step forms the oxide layer on the surface of the aluminum. The voltage, current, and duration of the process are carefully controlled to achieve the desired thickness of the oxide layer. Advanced equipment and experienced technicians ensure that these parameters are precisely managed, resulting in a high-quality and durable anodized finish.

Coloring is an optional step in the anodizing process, allowing for a wide range of aesthetic possibilities. Both organic dyes and electrolytic coloring methods can be used to achieve vibrant and long-lasting colors. Organic dyes provide a wide range of bright and visually appealing colors, while electrolytic coloring produces metallic tones with high UV stability. These coloring methods ensure that the anodized aluminum not only looks great but also maintains its durability and performance.

The final step in the anodizing process is sealing the oxide layer. This step is crucial for locking in the color and enhancing the durability of the anodized finish. Sealing involves treating the surface to close the pores of the oxide layer, providing long-lasting protection against corrosion and wear. Advanced sealing techniques ensure that the anodized finish is both visually appealing and highly durable.

Quality control is a vital part of the anodizing process. Each part undergoes thorough inspection to ensure that it meets the highest standards of quality. Inspection methods include measuring the thickness of the anodized layer, checking for uniformity and consistency, and verifying that the finish meets the required specifications. By conducting rigorous inspections, you can ensure that each anodized part is of the highest quality and ready for use in various applications.

Anodized aluminum plays a crucial role in the aerospace and aviation industries due to its exceptional combination of lightweight and high-strength properties. These characteristics are essential for components that need to withstand extreme conditions while minimizing weight to enhance fuel efficiency and performance. Additionally, the aesthetic appeal of anodized aluminum makes it suitable for both functional and decorative applications in aircraft interiors.

In the architecture and construction sectors, anodized aluminum is a preferred material for a wide range of applications due to its durability, aesthetic versatility, and low maintenance requirements. It is commonly used for window frames, facades, railings, and other architectural elements. The anodizing process not only enhances the corrosion resistance of aluminum but also allows for a variety of finishes, including different colors, textures, and gloss levels. This makes it an ideal choice for modern construction projects that require both functionality and visual appeal.

The automotive industry heavily relies on anodized aluminum for its performance parts, trims, and wheels. Anodized aluminum components are not only lightweight but also highly durable, making them ideal for enhancing the performance and longevity of vehicles. The anodizing process provides a protective layer that enhances the wear resistance and corrosion resistance of these parts, ensuring they can withstand the rigors of daily use.

Anodized aluminum is widely used in the medical device industry due to its biocompatibility, ease of cleaning, and durability. These properties make it an ideal material for surgical tools, lab equipment, and other medical devices that require high standards of hygiene and performance. The anodizing process enhances the surface properties of aluminum, making it more resistant to wear and corrosion while maintaining its biocompatibility.

Uneven coloration can be caused by improper dye application or inconsistent anodizing. Adjusting the process parameters can resolve this issue.

Burning or pitting can occur due to improper electrical or chemical conditions. Careful control of the anodizing process can prevent these issues.

Poor adhesion of dyes can be caused by surface contamination or improper dye application. Proper surface preparation and dyeing techniques can improve adhesion.

Inconsistent thickness can be caused by variations in the anodizing process. Adjusting the process parameters and ensuring uniform electrical contact can improve uniformity.

Proper cleaning is essential for maintaining the appearance and durability of anodized aluminum. Use mild soaps and avoid abrasives to prevent scratching the surface.

Protect the anodized finish by avoiding harsh chemicals and physical abrasion. Regular maintenance can extend the lifespan of the finish.

Anodized aluminum is designed to last. With proper care, it can maintain its appearance and functionality for many years.

Yes, anodized aluminum can be re-anodized. However, the existing oxide layer must be removed first.

Anodizing does not make aluminum stronger but enhances its surface hardness and durability.

Anodized aluminum is generally food-safe, but it is essential to ensure that the anodizing process complies with food safety standards.

Mastering the art of aluminum anodizing is essential for achieving high-quality, durable, and visually appealing products. Guangdong Anlv New Material Co., Ltd. offers comprehensive solutions for anodized aluminum products, ensuring optimal results and applications. Whether you are considering professional anodizing services or DIY projects, understanding the process and its benefits will help you achieve the best possible outcomes.