- Home

- Products

- OEM&ODM Services

- About

- Applications

- Resources

- Blogs

- Contact

Views: 0 Author: Site Editor Publish Time: 2025-08-07 Origin: Site

When it comes to choosing the right material for your project, understanding the differences between anodized aluminum and painted aluminum is crucial. At Guangdong Anlv New Material Co., Ltd., we specialize in providing high-quality anodized aluminum products that offer superior performance and durability. In this comprehensive guide, we will delve into the key differences between anodized and painted aluminum, exploring their applications, benefits, and how they stack up against each other.

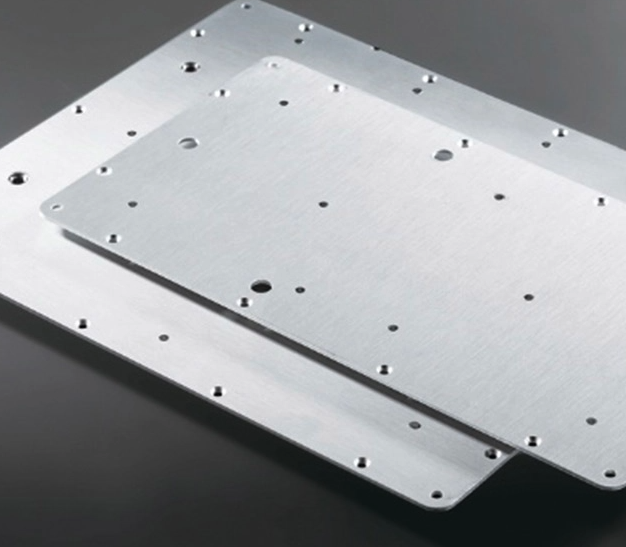

Anodized aluminum is a material that has undergone an electrochemical process to create a durable, corrosion-resistant surface. This process involves immersing the aluminum in an electrolytic solution, which forms an oxide layer on the surface. This oxide layer is part of the aluminum itself, bonded at the molecular level, making it highly durable and resistant to wear and tear.

Durability: The anodized layer is second only to diamonds in terms of hardness, making it highly resistant to scratches and abrasions.

Low Maintenance: Anodized aluminum does not chalk, flake, chip, or peel, ensuring a long-lasting finish with minimal maintenance.

Aesthetic Appeal: Anodized aluminum offers a natural metallic look that is highly desirable in modern design.

Environmental Resistance: The anodized layer protects the aluminum from UV rays, salt spray, and other environmental factors, making it ideal for outdoor applications.

Anodized aluminum is used in a wide range of applications, including:

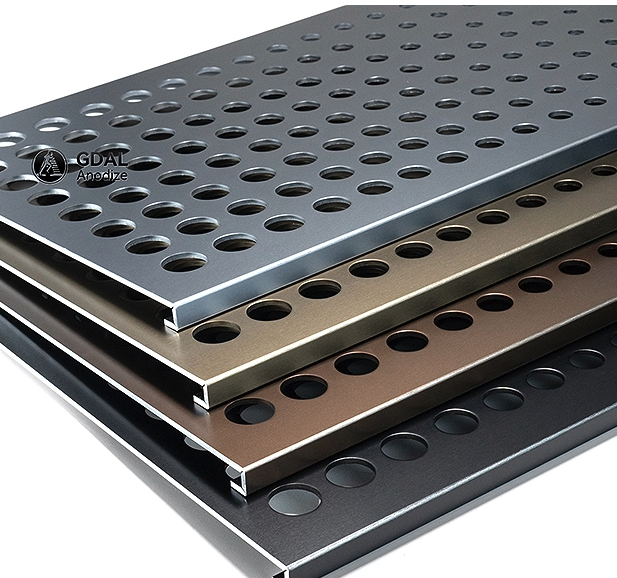

Architectural Facades: Anodized aluminum panels are commonly used for building exteriors due to their durability and aesthetic appeal.

Automotive Interiors: The material’s resistance to wear and tear makes it suitable for car interiors and trims.

Consumer Goods: Anodized aluminum is used in appliances, electronics, and other consumer products for its durability and modern look.

Transportation: Anodized aluminum is used in transportation vehicles, including high-speed trains and aircraft, for its lightweight and durable properties.

Painted aluminum involves applying a layer of paint to the aluminum surface. This can be done using various methods, including electrostatic application, liquid painting, and powder coating. Painted aluminum offers a wide range of color options and can be customized to meet specific design requirements.

Color Variety: Painted aluminum offers a broad spectrum of colors and finishes, allowing for greater design flexibility.

Aesthetic Customization: Painted aluminum can achieve unique finishes and textures that may not be possible with anodizing.

Cost-Effective: In some cases, painted aluminum can be more cost-effective, especially for projects requiring specific colors or finishes.

Painted aluminum is used in various applications, including:

Architectural Elements: Painted aluminum is often used for window frames, door profiles, and other architectural elements where specific colors are required.

Automotive Exteriors: Painted aluminum is used in automotive exteriors for its ability to achieve specific colors and finishes.

Signage: Painted aluminum is ideal for signage due to its ability to display vibrant colors and custom designs.

Anodized aluminum is renowned for its exceptional resistance to scratches and abrasions. This durability stems from the hard oxide layer that forms during the anodizing process. This layer is chemically bonded to the aluminum, making it an integral part of the material itself. As a result, anodized aluminum can withstand significant wear and tear, making it ideal for high-traffic areas and applications where the material is frequently exposed to physical contact. For example, in architectural applications such as door handles, window frames, and handrails, anodized aluminum maintains its appearance and functionality over extended periods without showing signs of wear.

In contrast, painted aluminum, while offering a wide range of colors and finishes, is more susceptible to scratches and abrasions. The paint layer is applied to the surface of the aluminum and relies on adhesion to stay in place. Over time, especially in environments with frequent physical contact, the paint can chip, scratch, or wear away, revealing the underlying aluminum. This not only affects the aesthetic appeal but can also lead to potential corrosion if the aluminum is exposed to the elements. For instance, in outdoor furniture or automotive exteriors, painted aluminum may require more frequent maintenance to keep it looking new.

Anodized aluminum excels in weather resistance, making it a preferred choice for outdoor applications. The anodizing process creates a protective oxide layer that is highly resistant to UV rays, salt spray, and other environmental factors. This layer prevents the aluminum from oxidizing or corroding, ensuring that the material maintains its structural integrity and appearance over time. For example, in coastal environments where salt spray is a significant concern, anodized aluminum can withstand the harsh conditions without degrading. Similarly, in areas with high UV exposure, such as southern climates, anodized aluminum does not fade or lose its protective properties.

Painted aluminum, while also designed to be weather-resistant, is more prone to degradation over time. Paint can fade due to prolonged exposure to UV rays, and the paint layer can chip or peel, especially in harsh environments. This can lead to areas of exposed aluminum that are vulnerable to corrosion. For example, in outdoor signage or architectural facades, painted aluminum may require periodic repainting to maintain its appearance and protect the underlying material. The risk of chalking, flaking, and peeling increases with time, especially in environments with significant temperature variations and exposure to moisture.

One of the most significant advantages of anodized aluminum is its minimal maintenance requirements. The hard oxide layer that forms during anodizing is highly durable and does not require repainting. This means that anodized aluminum can maintain its appearance and performance for many years with little to no maintenance. For example, in building exteriors or outdoor furniture, anodized aluminum can withstand the elements without the need for touch-ups or recoating. This not only saves time and effort but also reduces long-term maintenance costs.

On the other hand, painted aluminum typically requires more maintenance to keep it looking its best. Over time, the paint layer can chip, fade, or peel, necessitating periodic repainting or touch-ups. This is especially true in high-traffic areas or harsh environmental conditions. For example, in automotive exteriors or outdoor structures, painted aluminum may need regular inspections and maintenance to address any signs of wear or damage. The frequency of maintenance can vary depending on the specific application and environmental conditions, but it generally requires more attention than anodized aluminum.

Painted aluminum is highly versatile when it comes to color and finish options. This flexibility allows designers to achieve virtually any desired aesthetic, making it a popular choice for projects where specific colors or custom finishes are required. Whether it’s a bold, vibrant color for a modern facade or a subtle, textured finish for a sleek interior design, painted aluminum can meet these needs. The ability to match specific Pantone colors or create unique finishes gives architects and designers the freedom to bring their creative visions to life.

Anodized aluminum, while more limited in color options, offers a distinct and desirable aesthetic. The natural metallic look of anodized aluminum provides a sophisticated, modern appearance that is highly sought after in contemporary design. The range of available colors, such as silver, bronze, and black, can complement a variety of architectural styles and design themes. The anodizing process enhances the natural beauty of aluminum, giving it a unique, high-quality appearance that is both elegant and durable.

Anodized aluminum is renowned for its ability to maintain its appearance over time. The hard oxide layer created during the anodizing process is highly resistant to fading, chalking, and peeling. This means that anodized aluminum will continue to look as good as new for many years, even in harsh environmental conditions. The natural metallic finish of anodized aluminum adds a touch of elegance and sophistication to any project, making it a preferred choice for long-term aesthetic appeal.

In contrast, painted aluminum, while initially offering a wide range of colors and finishes, can be more susceptible to fading, chalking, and peeling over time. Exposure to UV rays, moisture, and other environmental factors can cause the paint to degrade, leading to a loss of its original appearance. This can be particularly noticeable in outdoor applications where the material is constantly exposed to the elements. As a result, painted aluminum may require periodic maintenance or repainting to maintain its visual appeal.

The initial cost of anodized aluminum can be comparable to painted aluminum, especially for clear anodized finishes. Anodized aluminum is often cost-effective for projects that require a durable, low-maintenance finish. The process of anodizing aluminum is relatively straightforward and does not involve the additional steps required for painting, such as priming and multiple coats. This can result in a more cost-effective solution, particularly for large-scale projects.

Painted aluminum, on the other hand, may be more expensive initially, especially for custom colors and finishes. The process of painting aluminum involves multiple steps, including surface preparation, priming, and application of multiple coats of paint. Custom colors and finishes can add to the cost, as they may require specialized pigments and processes. Additionally, the cost of paint and the labor involved in applying it can contribute to higher initial expenses.

Anodized aluminum offers significant long-term cost savings due to its durability and low maintenance requirements. The hard oxide layer created during anodizing is highly resistant to wear and tear, meaning that anodized aluminum will not require repainting or frequent maintenance. This can result in substantial savings over the life of the project, as there are no additional costs associated with maintaining the appearance and integrity of the material.

Painted aluminum, while offering a wide range of aesthetic options, may require periodic repainting or touch-ups to maintain its appearance. Over time, the cost of these maintenance activities can add up, resulting in higher long-term costs. The frequency of maintenance required will depend on the specific application and environmental conditions, but it is generally more than what is needed for anodized aluminum. This makes anodized aluminum a more cost-effective solution in the long run, particularly for projects that require a durable and low-maintenance finish.

Anodizing is recognized as an environmentally responsible process. The anodizing process involves creating a protective oxide layer on the surface of aluminum through an electrochemical reaction. This process produces minimal waste and emissions, making it a sustainable choice for many applications. The primary byproduct of anodizing is aluminum oxide, which is non-toxic and can be safely disposed of or recycled. Additionally, the anodizing process does not involve the use of harmful chemicals or solvents, reducing its overall environmental footprint.

Painted aluminum, particularly when using powder coatings, can also be environmentally friendly. Powder coatings are applied electrostatically and then cured in an oven, resulting in a durable and uniform finish. This method reduces the amount of volatile organic compounds (VOCs) released into the atmosphere compared to traditional liquid paints. However, the painting process may still require more energy and resources, especially when it comes to surface preparation, application, and curing. Additionally, the maintenance of painted aluminum, which may involve periodic repainting, can contribute to higher long-term environmental impact due to the repeated use of paints and coatings.

Both anodized and painted aluminum can comply with environmental regulations, but anodized aluminum often stands out for its minimal environmental impact. The anodizing process is designed to meet strict environmental standards, ensuring that it produces little to no harmful byproducts. This makes anodized aluminum a preferred choice for projects that prioritize sustainability and environmental responsibility.

Painted aluminum, while also capable of meeting regulatory standards, may require additional measures to ensure compliance. The use of powder coatings and other low-VOC paints helps reduce environmental impact, but the overall process can still involve more energy consumption and resource use. Additionally, the need for periodic repainting can lead to increased waste and emissions over time.

Choosing between anodized and painted aluminum depends on several factors, including:

Final Appearance: Consider the desired aesthetic and whether a natural metallic look or custom colors are more important.

Intended Use: Evaluate the application and environmental conditions to determine which material will perform best.

Maintenance Requirements: Consider the long-term maintenance needs and associated costs.

Budget: Assess the initial and long-term costs to determine the best value for your project.

Anodized aluminum is highly resistant to scratches, abrasions, and weathering due to its hard oxide layer. Painted aluminum can be more susceptible to chipping, fading, and peeling, especially in harsh environments.

Anodized aluminum requires minimal maintenance and does not need repainting. It maintains its appearance over time with little to no upkeep, making it cost-effective in the long run.

Painted aluminum may require periodic repainting or touch-ups to maintain its appearance, especially in high-traffic areas or harsh environments. This can increase long-term maintenance costs.

Anodized aluminum is ideal for outdoor applications due to its superior resistance to UV rays, salt spray, and other environmental factors. Painted aluminum can also be used outdoors but may degrade faster over time.

Understanding the differences between anodized and painted aluminum is essential for making the right choice for your project. Anodized aluminum offers superior durability, low maintenance, and a natural metallic look, making it ideal for outdoor applications and high-traffic areas. Painted aluminum provides greater design flexibility with a wide range of colors and finishes, making it suitable for projects with specific aesthetic requirements. By considering the factors outlined in this guide, you can make an informed decision that meets your project’s needs and ensures long-term success.

Ready to choose the best finish for your project? Contact Guangdong Anlv New Material Co., Ltd. for expert advice and high-quality anodized aluminum products. Our team is here to help you make the right choice for your project. Visit our website to learn more about our products and services.